OEM/ODM Factory Biscuit Packaging Machine - Automatic Wafer Packing Line L Type – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

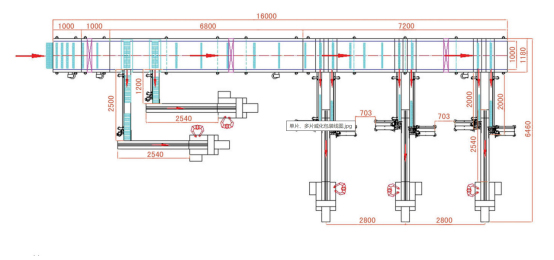

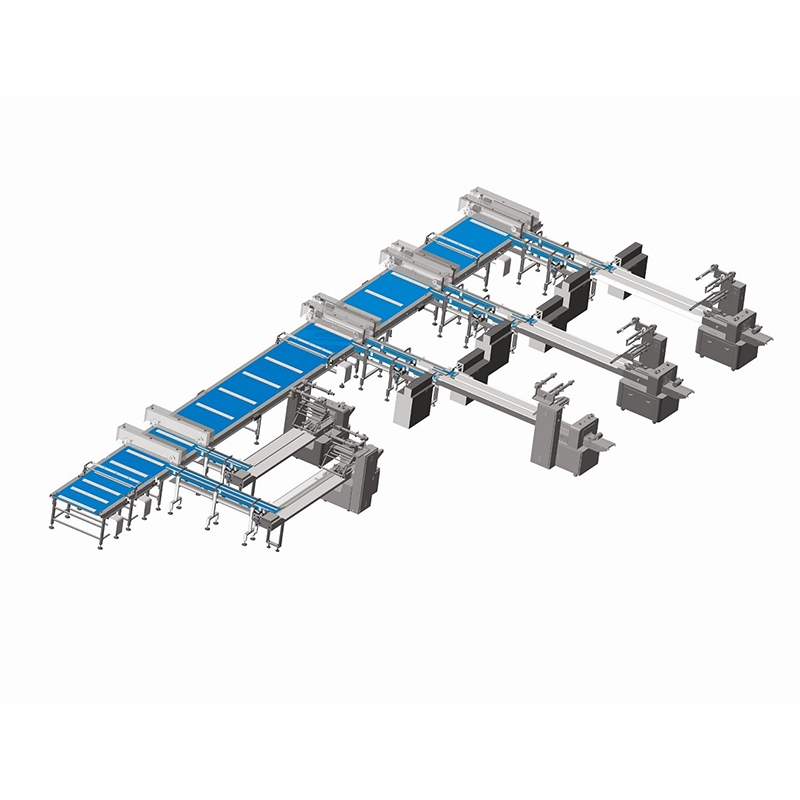

OEM/ODM Factory Biscuit Packaging Machine - Automatic Wafer Packing Line L Type – Temach Detail:

Product Detail

This automatic packaging system is designed for products with a tray or box, and this packing line can automatically load the tray and pack without any manual operation.

One worker can operate two lines, which helps to save labor costs for customers.

This feed-in and packing line are equipped with deoxidizer or deoxidizing agent pad feeder, tray sucking down unit, tray automatic loading unit and packaging machine.

The packing speed of the tray loading and packaging line is 100-120 bags per minute.

1. Product Introduction of Automatic Horizontal Wrapping Equipment for Swiss Roll

This wafer packaging system is a multi-function system, which can pack single wafer and multi-wafer. We designed the whole packing system according to your layout and inquiry. The maximum speed can up to 250 bags/ minute. The speed of the family pack depends on the size.

2. Main Function of Food Packing Machine for Wafer

The wafer packing line consists of a distance controller, reversing conveyor, auto sorting unit, and packing machine. This system will help wafer auto aligning, distanced, distributing, and delivering to the sorting unit and finish packing in order to keep a continuous and orderly production with lower waste and beautiful package. Alcohol spray and air charging are optional.

Single line packing speed can reach 80-220 bags/min.

The whole packaging system adopts 220V, 50HZ, single phase. Total Power is 26KW

The food packing system can use different packing models according to customer product inquiries.

3. Advantage of Automatic Food Packing System for Wafer Biscuit

The horizontal packing line equipped with an auto aligning device and protective cover. The auto-correcting device is optional.

Simplified structure, easy operation, convenient cleaning, and maintenance. Easy adjustment for different products or parameter settings.

The Control system uses high-quality electronic, intelligent PLC, touch screen, and good HMI, operating more simply and conveniently.

The flow packing line equipped with several different speed belt to arrange breads or cakes to guarantee high speed stably and locate accurately.

The automatic food packaging machine and system use stainless steel and Nylon baffle, easy for operation and cleaning.

PU belt can be discharged without tools in 1 minute and equipped with a hopper to get product waste, which easy for cleaning and maintenance.

The food machinery structure is very simple, easy operation, convenient for cleaning and maintenance. Easy adjustment for different products or parameter settings.

The Control system of the plastic film packaging equipment uses high-quality electronic, intelligent PLC, touch screen, and good HMI, operating more simply and conveniently.

We will add a 90-degree turning conveyor or 180-degree turning conveyor to the packaging system according to customers’ factory layout or space.

Equipped with meter detector and weight checker, which can automatically connect with the flow packaging system.

Wafer automatic food packaging machine equipped with an auto aligning device and the automatic correcting device for the belt is optional.

The packing line can align wafers (products) and deliver to the sorting unit orderly to guarantee high speed stably and locate them accurately.

PU belt of packing machine can be discharged without tools and equipped with hopper to get product waste, which easy for cleaning and maintenance.

Simplified structure, easy operation, convenient cleaning and maintenance. Easy adjustment for different products or parameter settings.

The wafer line control system uses high-quality electronic, intelligent PLC, touch screen, and good HMI, operating more simply and conveniently.

The PU belt of the wafer packaging line can use sticky proof in white color optionally.

4. Application of Automatic Packaging Machinery

Applicable for packing extruded food and other regular product, which made by cutting machines. Connected with former production line by automatic feeder or manual feeder.

5. Packaging Samples

6. Drawing of Automatic Packaging Solution

7. Packaging System Details.

(1) Distance controller

The main function of the distance controller is pull over the product distance or keep them in rows.

(2) Distributing conveyor

This distributing conveyor of the packaging solution is used to deliver products into different packaging lines. The length of these parts depends on customers’ production capacity or factory layout.

(3) Direction pusher

The direction pusher normally only use for wafer packaging system, which help change the wafer direction and deliver to the different packaging machine.

(4) Storage belt

The main function of the storage Belt is to storage those wafers and help deliver to the packaging machine, finish packaging.

(5) Servo pusher

Introduction: This servo pusher only uses for the family wafer packaging line. In order words, if you need 6pcs per bag (2layer and each layer 3 pieces ), then this part needs to order. If you just need to pack a single wafer, then no need for these parts.

Function: The main function is to push the group wafer into the infeed conveyor, then package.

(6)Sorting unit

Sorting unit of packaging system introduction:

The sorting unit parts are consist of 2 conveyor belts and 5-6 sensors.

The function of the sorting unit:

The main function of this sorting unit is to control the product feeding speed, located it, and connect it with the packaging machine automatically. Once it detected the product too much, the feeding speed will slow down, if lack of product, then the feeding speed will speak up soon.

Advantage of the sorting unit:

Reducing human operation and make sure the packaging machine running at a stable speed with fewer product wastes.

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for OEM/ODM Factory Biscuit Packaging Machine - Automatic Wafer Packing Line L Type – Temach, The product will supply to all over the world, such as: Istanbul, Ukraine, Russia, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!