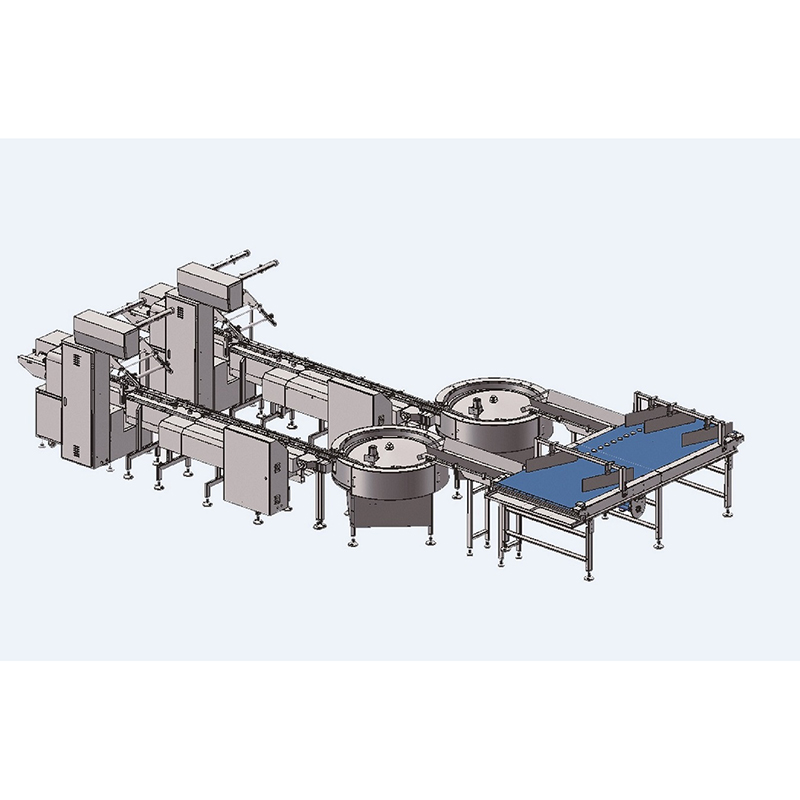

Automatic Disk Rotary Packaging Machine System

Short Description:

This rotary disk type flow packaging system is designed for products like egg roll, rice bar, rice roll, marshmallow, crunchy bar, nut crisp bar, wafer stick, oatmeal chocolate, flaky candies, pine cones, and pralines, cookies and other regular shape products etc. The packaging speed can be up to 350 bags per minute.

In-feed part can be customized according to actual needs.

It can communicate with upstream and downstream machines if needed.

Manual or automatic feedings are both possible.

Product Detail

Product Tags

Product Detail

1.Introduction of disk turntable type automatic packaging line:

The disk turntable type flow packaging system is designed for hard product, such as egg roll, rice roll, marshmallow, crunchy bar,nut crisp bar, wafer stick, cookies and other regular shape product. The packaging speed can up to 350 bags per minute. The packing line can manual feeding or automatic feeding product, it’s very convenient.

2.Main Function of disk turntable automatic packaging system:

Single disk turntable type packaging line packing speed can reach 150-350bags/min.

Whole packing system adopts 220V, 50HZ, single phase. Total Power is 11KW.(2 line of dis turntable packaging line)

The disk turntable type packing system can use difference packing model according to customers’ requirement or packaging specifications.

The flow packaging machinery qualified rate of products is up to 99%.

Electric eye induction of the packaging system is set at the feeding place of the soap. If the soap is not in place, the soap packing machine will not start packing.

The disk turntable type packaging machine can store various parameters (film length, feeding speed, bag length) simple and convenient, reasonable design. Suitable for mass production.

The feeding shaft, membrane transmission shaft and transverse sealing and cutting shaft of the soap packing machine are driven by separate servo motors, and each mechanism can be independently controlled. Parameters can be set according to different products and then stored in the PLC program.

The horizontal flow wrap packing machine with the function of automatic Angle insertion, make bag appearance more beautiful and the reliability is improved

Disk turntable type packing line consists of distance controller conveyor, feeder, disk turntable unit,auto sorting unit and packing machine. This system use disk centrifugal force to distributing and delivering to the sorting unit and finish packing in order to keep a continuous and orderly production with lower waste and beautiful package. Alcohol spray and air charging is optional.

3.Advantage of automatic food packing system for rice bar or cookies.

The horizontal packing line equipped with auto aligning device and protective cover. Auto correcting device is optional.

Packaging machine with simplified structure, easy operation, convenient cleaning and maintain. Easy adjustment for different products or parameter setting.

Control system of the packaging system uses high quality electronic, intelligent PLC, touch screen and good HMI, operating more simply and convenient.

The flow packing line equipped several difference speed belt arrange soap bar to guarantee high speed stably and locate accurately.

The automatic soap bar packaging machine and system use stainless steel and Nylon baffle, easy for operation and cleaning.

We will add 90 degree turning conveyor or 180 degree turning conveyor to packaging system according to customers’ factory layout or space.

Equipped with metal detector and weight checker, which can automatic connect with the flow packaging system.

The packing line can align device and deliver to sorting unit orderly to guarantee high speed stably and locate accurately.

Disk turntable unit delivers product to sorting unit to guarantee high speed stably and locate accurately.

Left and right hand version packing line available

The packing line allows changing among zig-zag cutter, wave cutter and strait cutter.

4.Application of disk turntable type automatic packaging solution:

This disk turntable automatic packaging solution is designed for hard product, such as egg roll, rice roll, marshmallow, crunchy bar,nut crisp bar, wafer stick, cookies and other regular shape product.

5.Packaging system details.

(1)Distance controller (Optional)

The main function of the distance controller is pull over the product distance or keep them in rows, then it’s easy to delivery to the feeder for the packaging system arrangement. For disk turntable type packaging line, if the capacity is small or customer want manual feeding products, this parts is optional.

(2)Feeder

The feeder of packaging system is use to deliver products to different packaging machines.

(3)Disk turntable unit

Through the centrifugal force of the rotation of the disk turntable, the material is thrown onto the outer ring for queuing output and packaging.

(4)Sorting unit

Sorting unit of packaging system introduction:

The sorting unit parts is consist of 2 conveyor belts and 5-6 sensors.

Function of the sorting unit:

The main function of this sorting unit is controlled the product feeding speed, located it and connect with the packaging machine automatically. Once it detected product too much, the feeding speed will slow down, if lack of product, then the feeding speed will speak up soon.

Advantage of the sorting unit:

Reducing human operation and make sure the packaging machine running in stable speed with less product wastes.

Display