OEM Customized Meaning Of Polysorbate - High Shear Mixers – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM Customized Meaning Of Polysorbate - High Shear Mixers – Temach Detail:

Details

It carries out a process of efficiently, rapidly and evenly transferring one or more phases (liquid, solid, gas) into another incompatible continuous phase (usually liquid). In general, each phase is incompatible with each other. When the external energy is input, the two materials are reconstituted into homogeneous phase. Due to the high tangential velocity generated by the high speed rotation of the rotor and the strong kinetic energy brought by the high-frequency mechanical effect, the material is subjected to strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, impact tear and turbulence in the narrow gap between the stator and the rotor, resulting in suspending liquid (solid / liquid), emulsion (liquid / liquid) and foam (gas / liquid). So that the insoluble solid, liquid and gas phases can be dispersed and emulsified uniformly and fine instantaneously under the combined action of the corresponding mature technology and appropriate additives, and then stable high-quality products can be obtained through high-frequency cycling and reciprocating.

Features of High Shear Dispersing Emulsifier

1. Large processing capacity, suitable for continuous industrialized online production;

2. Narrow particle size distribution and high uniformity;

3. Time saving, high efficiency and energy saving;

4. Low noise and stable operation;

5. Eliminate quality differences between batches;

6. The suction port of the homogenizer can directly suck part of the raw material into the rotor and cut it out of the pump body;

7. No dead angle, 100% of the material is sheared through dispersion;

8. With short-distance, low-lift conveying function;

9. Simple to use and easy to maintain;

10. Can realize automatic control.

Applications of High Shear Mixers

High shear mixers can be seen from all industries requiring ingredients to be combined. Below are applications of high shear mixers.

Food Manufacturing

There is a wide range of high shear mixer applications under this category. High shear mixers used in the food industry can create emulsions, suspensions, powders, and granules. A popular application is the manufacture of sauces, dressings, and pastes. Most of the ingredients are composed of solid particles, and immiscible liquids such as oil and water.

Some ingredients are more difficult to process such as ketchups, mayonnaise, and doughs. These liquids and semi-solids have viscoelastic properties which require a minimum force before creating flow. This requires specialized rotor-stator mixing heads.

Pharmaceuticals and Cosmetics

Like in the food industry, pharmaceuticals deal with different types of mixtures. Inline high shear mixers are used due to its closed system eliminating any intrusion of contaminants. All pharmaceutical products such as tablets, syrups, suspensions, injection solutions, ointments, gels, and creams go through a high shear mixer, all of which have varying viscosity and particle size.

Paints and Coatings

Paints (latex) are known to be a non-Newtonian, thixotropic liquid. This makes paints difficult to process. Paint thins as it is being sheared, either by processing or by end-use. Mixing time for these fluids are carefully controlled to prevent over shearing.

Inks and Toners Manufacture

Viscosity of inks (printer) is the opposite of paints. Inks are considered rheopectic. Rheopectic fluids thicken as it is being sheared, making the mixing process time dependent.

Petrochemicals

Applications under this category include combining resins and solvents for casting or injection molding, modifying oil viscosity, emulsifying waxes, asphalt production, and so forth.

Display

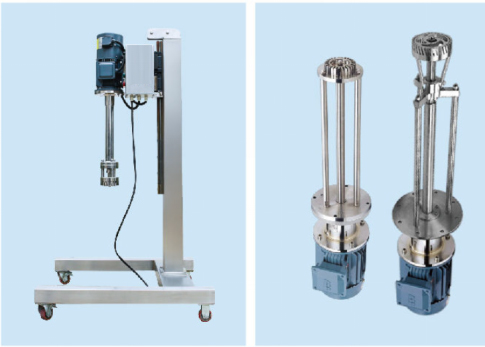

Product detail pictures:

Related Product Guide:

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for OEM Customized Meaning Of Polysorbate - High Shear Mixers – Temach, The product will supply to all over the world, such as: Juventus, Riyadh, Bolivia, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.