OEM Manufacturer Mining Hammer Crusher - HML Series Hammer Mill – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM Manufacturer Mining Hammer Crusher - HML Series Hammer Mill – Temach Detail:

Advantages

Excellent design to make online or offline sterilization possible.

1. The highest speed is 6000 rpm, 50% higher than that of the competitors’;

2. The screen has a larger effective area, which is about 30% higher than the traditional punching plate screen;

3. Intuitive and simple operation of HMI touch panel;

4. Smart design minimizes moving parts;

5. Clamp type assembly design, convenient for disassembly and modular assembly;

6. The head can be easily separated from the fuselage for offline sterilization;

7. Stainless Steel construction – ideal for Food & Pharmaceutical Processing;

Better Performance

1.The machine head can be disassembled with clamps, easy for maintenance;

2.Safety opening without cables, easy for cleaning;

3.Semicircle screens are designed with up to 40% opening rate, good for output;

4.Easy for operation and quick for assembly.

Working Principle

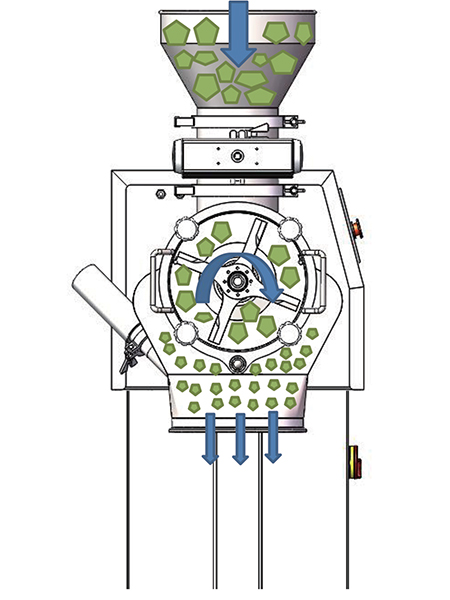

The head of HML series hammer mills is composed of a screen, a rotary knife and a uniform feeding valve. The material enters into the crushing chamber through the uniform feeding valve, passes trough the high speed impact of the rotor, and passes through the screen to get the required particle sizes.

Design Characteristics

1.The core components and bearings of the hammer mills are of NSK bran, the electrical parts are of Danfoss, Siemens, Schneider and equivalent famous brands;

2.Compact structure, easy for using and cleaning. Design meets GMP requirements, and can realize sterilizing online or offline;

3.Feeding hopper, uniform feeding valve, pulverizer and pulverizing screens are easy for installation;

4.Mirror polishing make it without clean dead angle, special structure design makes it with less temperature raising during milling process;

5.The combination of multi-functional design facilitates more flexibilities for users.

Technical Parameters

| Model | Capacity | Speed | Power | Weight |

| HML-200 | 10~100kg/h | 1000~7000rpm | 4KW | 200kg |

| HML-300 | 50~1200 kg/h | 1000~6000rpm | 4KW | 260kg |

| HML-400 | 50~2400 kg/h | 1000~4500rpm | 7.5KW | 320kg |

Display

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and superb good quality control throughout all stages of manufacturing enables us to guarantee total buyer gratification for OEM Manufacturer Mining Hammer Crusher - HML Series Hammer Mill – Temach, The product will supply to all over the world, such as: Venezuela, Poland, New Zealand, If you need to have any of our merchandise, or have other items to be produced, make sure you send us your inquiries, samples or in depth drawings. Meanwhile, aiming to develop into an international enterprise group, we look forward to receiving offers for joint ventures and other cooperative projects.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.