OEM/ODM Supplier Sauce Packing Machine - Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods) – Temach

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM/ODM Supplier Sauce Packing Machine - Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods) – Temach Detail:

Product Detail

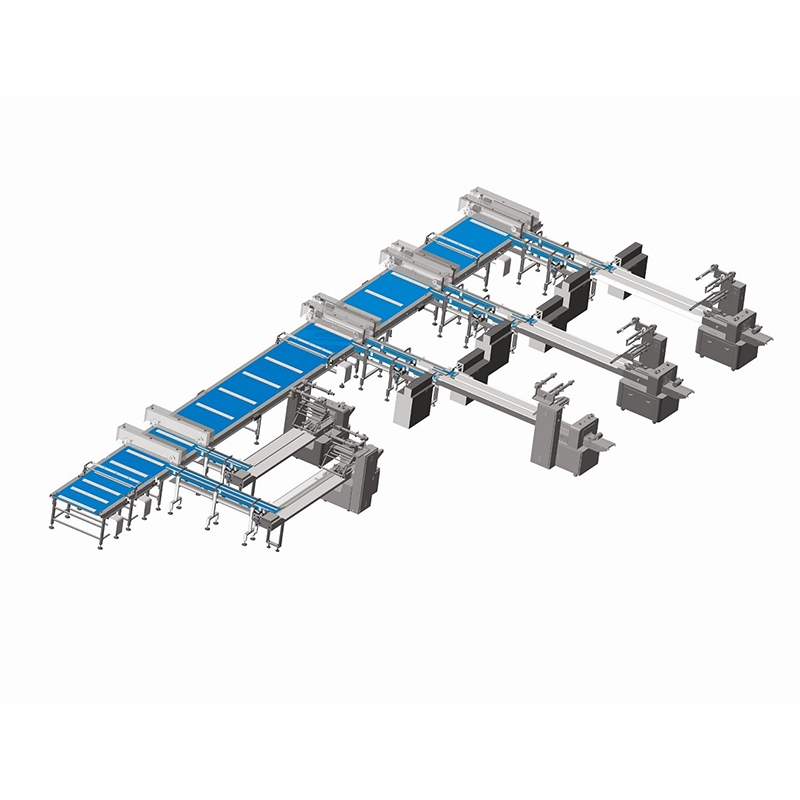

1. The automatic feeding system is selected according to the products‘ incoming condition and the packing requirements. Products feed-in conditions includes: material characteristics, processing technology, capacity, status, arrangement direction, etc. The packing requirements includes: single, multi-pack assembly, adding support box, positive and negative, etc.

2. According to the stable operation speed of different feeding packing line, to match the demand of customer’s production capacity, design the scientific, reasonable and efficient planning scheme.

Characteristics

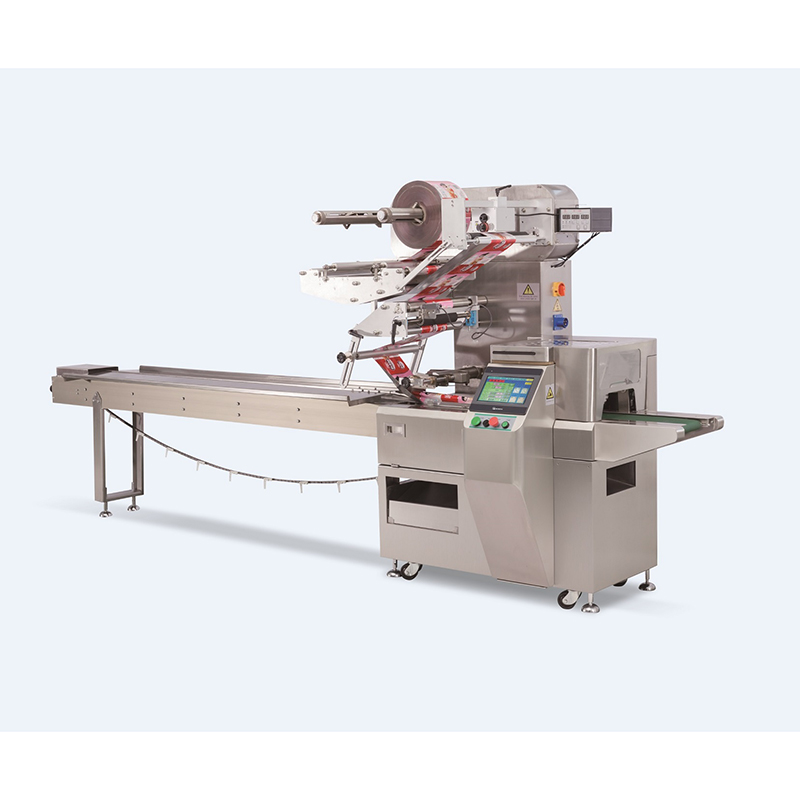

1. The automatic feeding system is designed by professional industrial appearance designers. According to the aesthetic viewpoint and principle, the transmission and functional structure are further optimized, the aesthetic degree and operability are fully considered, and the high-end brand image is molded.

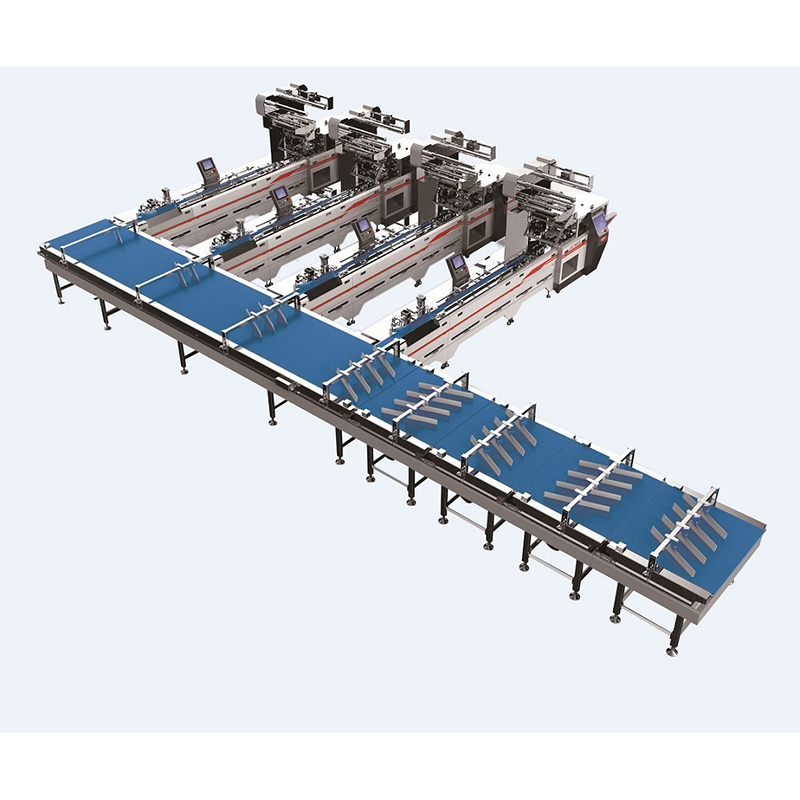

2. The separation arraying conveyor can realize the orderly arrangement of products, high-speed and stable, and easy to operate.

3. The conveyer belt of automatic feeding system can disassemble and disassemble quickly without tools. The bottom and interface of conveyor belt are equipped with slag slot, which is convenient to maintain and clean equipment, save time and effort.

4. The whole line selects high-quality food grade conveyor belt.

5. Control system uses high-quality electrical components, equipped with servo motor, PLC control, touch screen operation display, good man-machine interface, simple operation, intuitive, convenient.

Equipment Advantage

1. The automatic feeding system normal combined by separation arraying conveyor, automatic feeding system and automatic packing machine, different types of systems, with corresponding alternative functions to meet customer packing needs.

2. The working speed of automatic feeding system is 100-600pcs/min by single kind product.

3. The automatic feeding system power is about 1.2kW.

Display

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for OEM/ODM Supplier Sauce Packing Machine - Automatic Packing Lines (Automatic feed-in system + Flow wrappers for foods) – Temach, The product will supply to all over the world, such as: Philippines, Swiss, Ecuador, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.